Trevor Johnson (with Martha) and Chris Newey from T H WHITE Dairy outside the four DeLaval VMS parlours.

Choosing to invest in robotics seems to be a popular decision for many UK farmers these days, for many different reasons. So when a robotic system forms part of a greenfield development project and a new dairy facility is conceived on a ‘blank sheet of paper’, it’s easy to see how utilising a combination of robotics can really make the benefits add up.

Addingrove Farm is a 240 acre dairy farm located near Aylesbury, with approximately 300 cows on-site and is a joint venture between P J Johnson & Sons and Chilton Home Farms Ltd which is run by the Johnson family. Together with nearby Canon Court Farm, also part of the estate, a total of nine DeLaval VMSTM V310 robotic milking stations and a host of robotic assistants have been planned into a sizeable development scheme.

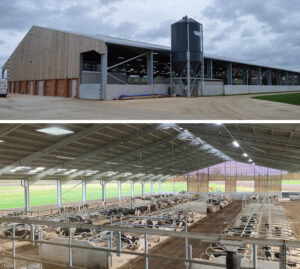

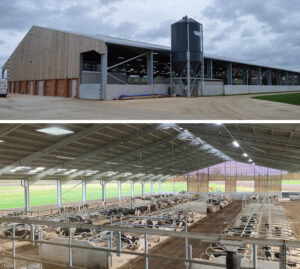

Situated on heavy clay ground where crops, unlike grass, are difficult to grow, Addingrove has naturally focused on dairy farming. The new facility went from greenfield site to state-of-the-art shed in just over a year, with DeLaval robotic equipment supplied and installed by Chris Newey and the T H WHITE Dairy team. The build commenced in January 2022 and was ready to accept cattle in March this year. With a capacity to house 220 cows, the fully-slatted shed has a huge 5.5M litre underground space. ‘You could fit a multi-storey car park under here’, Chris smiles. The excavated earth was re-used to create adjacent land banks with a series of oak tree plantations, in the interests of reaching carbon neutrality. To aid this goal further, an environmentally-friendly ‘bubbler’ slurry management system was installed to reduce the volume of methane produced, by aerating the muck – all helping to futureproof the shed from upcoming changes in methane regulations.

The hugely impressive facility at Addingrove Farm.

Prior to investing in the DeLaval VMS system, Trevor Johnson visited 17 robotic farms nationwide during an extensive research phase, ensuring the most successful products and processes were brought on-board. ‘We saw the DeLaval system as the way forward, as it clearly improved hygiene, animal welfare, productivity and ultimately, profitability’, he says.

Four robotic DeLaval VMS 310 systems were installed in early Spring and milking quickly began in mid-March. The reason for the cows successful adjustment from conventional to robotic milking is simple, according to Trevor. ‘There are no humans involved, so the cattle are very happy’, he states. ‘A natural pecking order has been set within the herd, there’s no need to force them to get milked at a certain time, and no lengthy queues or lame cows standing on concrete. They’re incredibly content and I’m delighted with how quickly they’ve adjusted.’

Indeed, ‘cow comfort’ is high on the agenda at Addingrove. Cattle lay on water beds for maximum comfort and hygiene, in what looks and feels like a five-star environment for cows. As Trevor recalls, ‘one visiting vet was quite taken with the water beds and noted how the cows were lying, commenting: ‘‘Clever cows tuck their tail under, comfy cows don’t need to. While they’re laying so comfortably, they’re actually making good milk.’’

As soon as installation was complete, it was noted that some of the cows proved to be ‘early-adopters’ – walking through all four robotic stations to try them out, before settling on a favourite machine. Trevor explains: ‘The whole idea is that during lactation, they don’t need to leave the shed other than to graze in the Summer. The mobility of the herd is very important, so the robotics, combined with the new layout, have done wonders to improve the constant flow throughout the shed.’

The DeLaval OptiDuo Robotic Feed Pusher at work.

The four VMS parlours.

Robotic milking in action.

The upper level area at the new facility is equally impressive, containing a number of spaces to support a wide range of activities. This includes a space to sell milk direct to the public through vending machines, a fitted kitchen, a computer & CCTV room, offices, and a large 40 seater meeting room – perfect for Young Farmers and local agricultural working groups to hold gatherings – as well as providing a superb viewing gallery which overlooks the herd below.

From left to right: The vast 5.5 million litre capacity slurry pit, DeLaval cooling tank, meeting room and viewing area.

In addition to the DeLaval VMSTM system, T H WHITE Dairy have supplied Addingrove with a series of robotic assistants and specialist equipment to enhance overall productivity:

DeLaval OptiDuoTM Robotic Feed Pusher: travels up and down the feed fence, pushing feed back to the cattle for easier access – keeping the feed rotated, bacteria-free, cool and fresh. This unit makes approx 8-9 active passes a day. Trevor explains, ‘The more often you push the feed, the more the cows move, the more they eat, and the more milk they generate.’

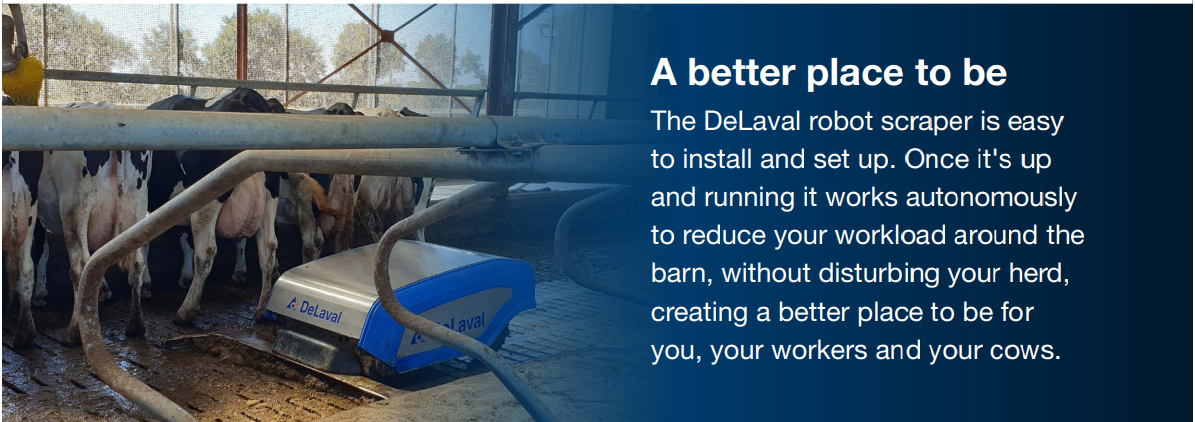

DeLaval Robotic Scraper: ‘This pushes slurry down the slats autonomously and thoroughly, with sensors built into the slatted floor that give the scraper instructions as to where to go,’ Chris points out. ‘It’s also quiet, so doesn’t bother the cows’.

DeLaval Cow brush: several brushes are on hand to provide a convenient, ergonomic and safe way for cows to scratch themselves in the shed.

Handling Race: features an automated gate opening which channels cows into a designated semi-circular area, where they receive hoof treatment, ear tagging, fly dabbing plus a dedicated footbath on the way out. Support from two staff is required to help direct the cows and carry out treatments.

DairyLight lighting: aids the cows’ sleep pattern and overall well-being. Alternating between red (for night-time) and blue/white light, helps regulate body clocks by exposing cows to a continuous spectrum of light for 16 -18 hours per day. Leads to increased yields, reduction in carbon footprint and increased profits.

From left to right: DeLaval OptiDuo Robotic Feed Pusher, DeLaval Robotic Scrapers & Cow Brushes, Handling Race and DairyLight Lighting.

Contact Chris Newey at the T H WHITE Dairy team on 07880 798475 for more info on DeLaval’s comprehensive range of products and our bespoke design engineering service.

This first of its kind role aims to improve relationships and collaboration between tenant farmers, landowners and advisers.

This first of its kind role aims to improve relationships and collaboration between tenant farmers, landowners and advisers. Supporting rural communities

Supporting rural communities

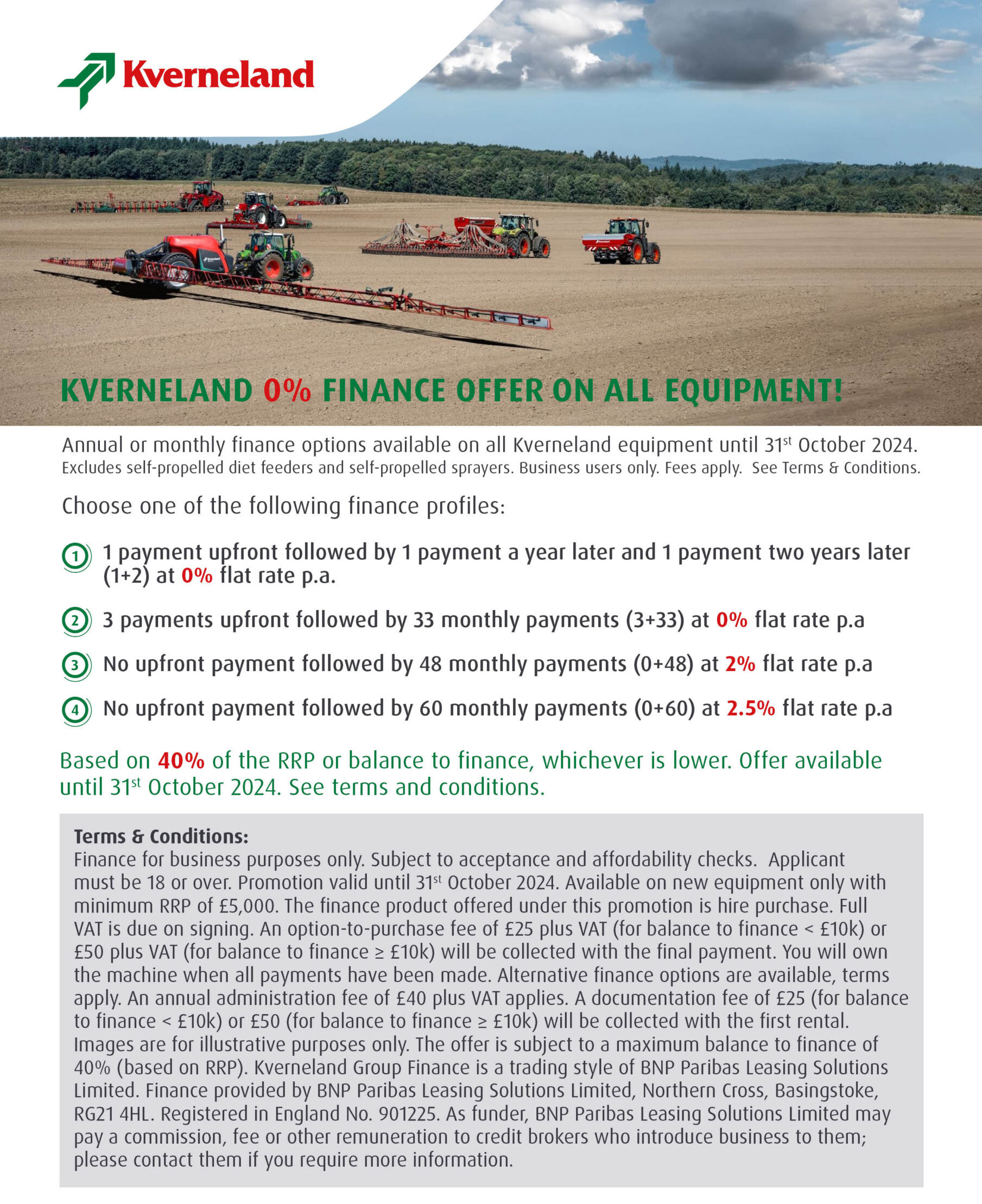

After a number of improvements, this latest tractor from Case IH, the Optum 340 CVX Drive is no heavier than the existing 300 and 270 models but provides more power, productivity and the ability to handle a wider range of tasks. Case suggests the Optum 340 CVX Drive is ideal for high draft and power take-off applications, whether they be tillage or grassland orientated with transport also being recognised as a regular task to which it is well suited.

After a number of improvements, this latest tractor from Case IH, the Optum 340 CVX Drive is no heavier than the existing 300 and 270 models but provides more power, productivity and the ability to handle a wider range of tasks. Case suggests the Optum 340 CVX Drive is ideal for high draft and power take-off applications, whether they be tillage or grassland orientated with transport also being recognised as a regular task to which it is well suited. The company has embraced the concept of Tractor Implement Management (TIM), which allows certified implements to automatically control specific tractor functions and although not fitted as standard, the software can be upgraded to accommodate this feature.

The company has embraced the concept of Tractor Implement Management (TIM), which allows certified implements to automatically control specific tractor functions and although not fitted as standard, the software can be upgraded to accommodate this feature.

B

B