CROSSOVER HARVESTING: THE NEW HOLLAND CH7.70

1st September 2020

New Holland has set a new benchmark for mid-range combine harvesters with the introduction of the CH7.70 – the first in a new line that introduces the concept of ‘Crossover Harvesting’.

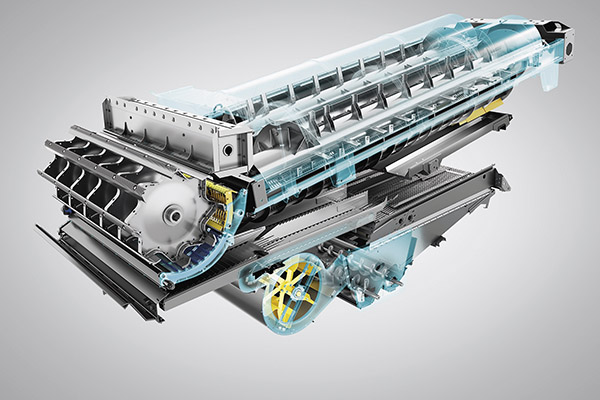

By bringing its outstanding Twin Rotor® separation technology together with its proven large diameter threshing drum, New Holland now offers users the best of both worlds in a machine designed to deliver up to 25% higher throughput than a conventional combine in this segment.  The two-drum threshing system features a 600mm diameter drum for gentle threshing that delivers very high grain and straw quality. The real benefit comes in combining this with a specially designed new version of New Holland’s Twin Rotor® separation technology. The 21-inch, 3.45-metre-long Twin Rotor system provides the largest separation area in the segment, at 2.9m2.

The two-drum threshing system features a 600mm diameter drum for gentle threshing that delivers very high grain and straw quality. The real benefit comes in combining this with a specially designed new version of New Holland’s Twin Rotor® separation technology. The 21-inch, 3.45-metre-long Twin Rotor system provides the largest separation area in the segment, at 2.9m2.

Pioneering the Crossover Harvesting brand, the new CH7.70 sits between New Holland’s mid-range conventional, and flagship rotary models, with a machine that is equally at home in all crops and conditions, delivering consistent, high performance in all conditions for arable farmers and contractors alike.

The CH7.70 features the proven Cursor 9 engine that develops 374hp – 34hp more than the CX6.90 – for powerful and fuel-efficient performance in all conditions. Patented HI-eSCR 2 technology enables it to comply with Stage V emissions standards too. With only four greasing points, daily maintenance is quick and simple and the large service door on top of the straw hood door provides easy access.

The CH7.70 features the proven Cursor 9 engine that develops 374hp – 34hp more than the CX6.90 – for powerful and fuel-efficient performance in all conditions. Patented HI-eSCR 2 technology enables it to comply with Stage V emissions standards too. With only four greasing points, daily maintenance is quick and simple and the large service door on top of the straw hood door provides easy access.

Only minimal changes in threshing setting are needed when switching between different crops, which can be carried out in less than 20 minutes.

The CH7.70 can be equipped with a range of Varifeed™ headers of up to 9.15 metres, including a brand-new 8.53-metre Varifeed version specifically developed for this range. The front face of the feeder housing can be mechanically adjusted to ensure perfect alignment with the header, thereby optimizing the angle for each different header to deliver smoother, layered crop flow, ensuring the best flow whatever the crop.

The cleaning capacity of the CH7.70 is perfectly matched to its high threshing and separation throughput. It features the unique New Holland Triple-Clean™ cascaded cleaning system, which boosts cleaning capacity by up to 15% with the addition of an extra cascade in the centre of the grain pan. The double flight cross auger also transfers grain to the elevator faster

Working on sloping ground is no problem for the CH7.70 either, thanks to the SmartSieve™ system, which automatically compensates for side slopes up to 25%. For sustained performance in hilly conditions, a Laterale version, which uses a robust automatic levelling system, provides transversal slope correction of up to 18% on both sides.

Driver comfort and has not been overlooked either. The 3.12m³ Harvest Suite cab is much larger than its nearest rival, and you can enjoy all that space in sound-insulated and air conditioned comfort. The wide, curved glass area offers a perfect view of the entire header and unloading spout.

Like all New Holland combines, the CH7.70 is covered by the standard three-year extended warranty (1,200 engine hours) which applies to the engine, driveline and after-treatment system. Protection like that is enormously valuable in providing peace of mind for the user, not only in terms of confidence in the exceptional quality of the product, but also in providing clear ‘Total Cost of Ownership’ for the buyer.

If you would like to find out more about the Crossover Harvesting concept and why the New Holland CH7.70 could be right for you. you, contact your T H WHITE sales representative