FOCUS ON QUALITY FORAGE WITH KUHN

2nd February 2021

Making the right grass machinery choices is vital for achieving the best results. Forage quality is increasingly recognised as a key driver in livestock farming profitability and, as a result, more farmers are taking greater control of the harvesting process by investing in their own machinery.

Key considerations when buying grassland machinery will include cost of ownership and operational efficiency, but there are also significant points to bear in mind around in-field performance, such as, maximising forage quality and minimising impurities during the mowing, tedding, raking, merging, baling and wrapping processes.

Ultimately, any forage harvesting system needs to be affordable, but if the result is sub-standard feed in the bale or the clamp it could be a false economy. Forage production can be boosted through the use of more advanced grassland machinery technology.

KUHN’s product specialist Katie Calcutt highlights some of the quality forage kit solutions available for merging, baling and wrapping:

“KUHN’s Merge Maxx 950 belt merger is a viable alternative to a four-rotor grass rake. With two adjustable, variable width and bi-directional merger belts, the Merge Maxx offers a maximum grass pick-up width of 9.50 metres. The bi-directional design also provides multiple windrow delivery options – forage can be delivered into a single central windrow, a single lateral windrow (left or right side), two lateral windrows (one either side) or a central and left or right lateral windrow.

“Auto-regulating rollers at the front and side of the pick-up unit self-adjust their position according to crop thickness. These, in turn, pass a consistent and constant supply of forage to the merger belts, thus enabling the machine to produce a uniform, airy and faster-drying windrow which makes it easier for the subsequent baler or chopper to collect large volumes of material. For forage harvesters, this can equate to a 2-3 km/hr increase in forward operating speed.

“The Merge Maxx is also designed to collect a clean crop with minimal impurities, with this being controlled by three key design elements: articulated pick-up skids, powerful LIFT-CONTROL springs, and pivot points which provide vertical and angled ground clearance. As well as ensuring good forage quality, less debris within the swathe also translates to less time and money spent on replacing blades and other working parts on the forage harvester or baler.

“At work, the Merge Maxx can handle a variety of materials, including the most delicate forage crops as well as straw, and always preserves the full nutritional value of the harvest.

“Making the best quality forage should be the priority for most, so for baled silage that means achieving a tight seal with sufficient wrap in the right areas to minimise the risk of air ingress during transport and storage,” Katie says.

“KUHN’s 3D wrapping is a system that packs a tighter bale by removing more air and ensures the edges of the bale are better protected by creating a 20cm overlap across this vulnerable zone. It also prevents rigid grass stems from puncturing the first layers of film by applying the film in the same direction that the bale is turning on the wrapping table.”

The cylindrical wrap ensures that more air is excluded and that the bale retains its shape.

“It’s important to have the optimum number of layers of film, and that will vary depending on a number of factors. On many KUHN bale wrappers or baler-wrapper combinations the KUHN Intelliwrap automated bale wrapping control system can be specified. In addition to allowing the flexibility of selecting single layer increments, this system combines sophisticated electronics and hydraulics, continuously monitoring film overlap during the wrapping process, delivering ultimate control and flexibility.

“If speed of operation and efficiency of film use are priorities, then KUHN’s e-Twin system will be of interest. This technology is available on several round bale wrappers and applies two layers of film simultaneously, thereby reducing the labour and fuel required to wrap a bale by up to 50%. The system makes further cost savings by pre-stretching the film by up to 90% so that one roll of film can cover a larger number of bales.”

Greater production from forage is a key part of future sustainable livestock farming, Katie Calcutt concludes, so it’s important to consider modern machinery technology to improve efficiency of operations and the quality of conserved feed.

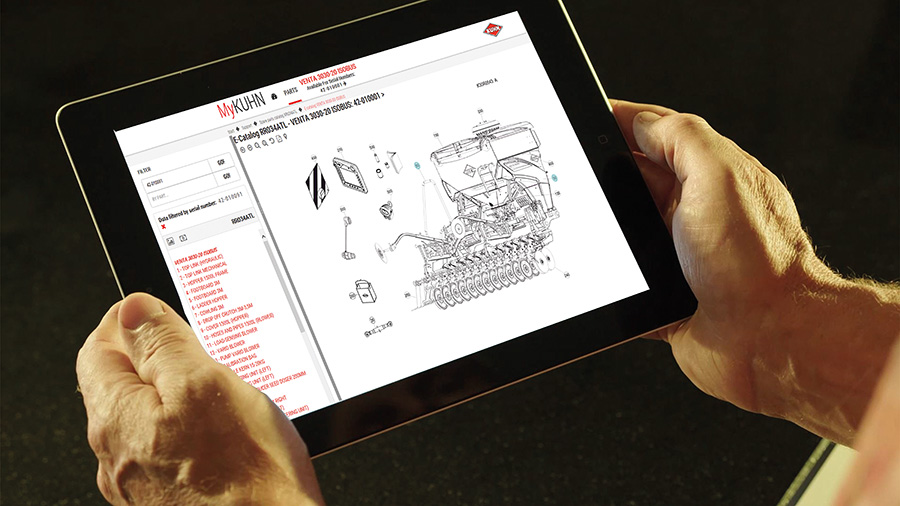

MyKUHN – Free access to your machine Operator Manuals

QUICK ACCESS

MyKUHN offers you essential information for maintenance and repairs, simply by registering your machine’s serial number on the site, even when purchasing used equipment. Your machine operator manual and any additional machine instructions can be found in the ‘SUPPORT’ tab of your MyKUHN account.

STORES YOUR OPERATOR MANUALS IN ONE PLACE

You can register more than one machine in your MyKUHN account, simply by adding additional serial numbers to your ‘MACHINE FLEET’. This will allow you to access all of your machine operator manuals in one place and store them in a safe place online!

DOWNLOAD AND PRINT

You can either read the pages of the manual you require online in MyKUHN or you can download the PDF file to print. It’s up to you!

To take advantage of My Kuhn, visit MyKUHN mykuhn.kuhn.com/uk

SAVE TIME AND FILM

RW –10 SERIES e -TWIN online calculator

Besides a standard single stretch, KUHN introduces the RW 10 series of round bale wrappers with e -TWIN technology for excellent cost-efficient wrapping.

The innovative e -TWIN technology enables wrapping via a unique combined pre-stretcher design with patented film distribution to save 50% on wrapping time and also on film costs. The conical pre-stretch rollers have been positioned in such a way that the two 750mm film wraps with 2/3 overlap are glued together providing a double layer before they leave the pre-stretcher unit.

Advantages of e -TWIN:

- Save 50% on wrapping time

- Further film saving achieved by increased pre-stretch ratio

- Tighter wrapped bales increases the airtightness and so quality of feed is also increased

- Extreme tear resistance under all circumstances

- Available on manual, joystick and computer versions

Check out how e -TWIN technology can bring cost efficiency for your wrapping business here https://www.kuhn.com/zoom/online-apps/wrapping-calculator/en/investment.html